China OEM China Wear Resistant Material Mining Welding Chromium Carbide Overlay Wear Steel Plate Nm500 Ar500 Alloy Steel Plate Wear Resistant Steel Plateod

We also present product or service sourcing and flight consolidation companies. We’ve our own manufacturing unit and sourcing office. We can easily provide you with nearly every form of merchandise similar to our product variety for China OEM China Wear Resistant Material Mining Welding Chromium Carbide Overlay Wear Steel Plate Nm500 Ar500 Alloy Steel Plate Wear Resistant Steel Plateod, Our concept would be to assist presenting the confidence of each prospective buyers while using the offering of our most honest service, as well as right merchandise.

We also present product or service sourcing and flight consolidation companies. We’ve our own manufacturing unit and sourcing office. We can easily provide you with nearly every form of merchandise similar to our product variety for China Steel Plate, Hard 400/500, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you personally.

WD1000/WD1100 series

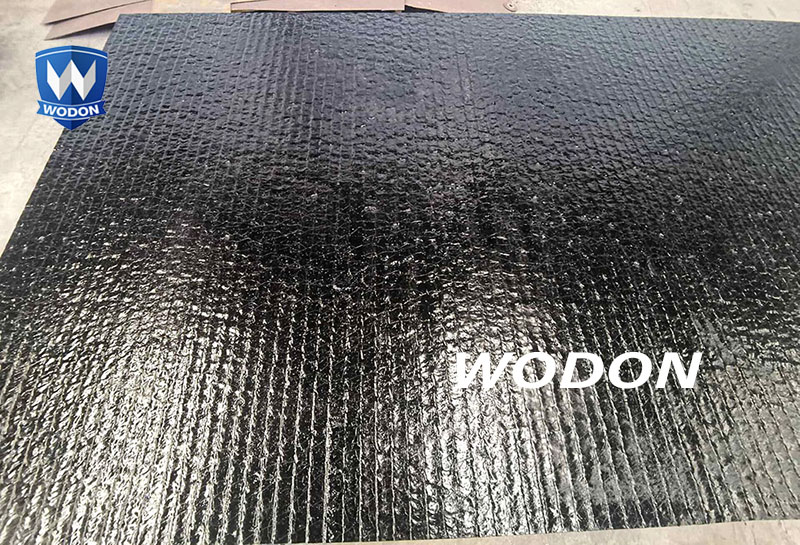

Abrasion Resistant Chromium Carbide Overlay

WD1000/WD1100 is chromium carbide composite cladding fusion bonded to a mild steel backing plate. The deposit has been realized by means of flux cored arc welding. WD1000/WD1100 wear plate is suitable for application involving high abrasion and low to medium impact.

● WD1000/WD1100 series:

Common chromium carbide wear plates produced by flux cored arc welding; Suited for applications involving high abrasion and low to medium impact.

|

Chemicals |

Hardness |

Sheet Size |

Base Metal |

|

C – Cr – Fe |

HRC 58-63 |

1400*3400 |

Q235/Q345. etc |

| Chemical Composition(%) |

C |

Cr |

Mn |

Si |

Fe |

Other |

|

3.0-5.0 |

15.0-35.0 |

1.0-3.0 |

1.0-3.0 |

Bal. |

- |

|

| Hardness |

HRC 58-65 |

|||||

| Standard Thickness(mm) |

3+3; 4+4; 5+5; 6+4; 6+6; 8+4; 8+6; 8+8; 10+10; 12+12; etc (overlay thickness up to 50mm) |

|||||

| Standard Sheet Size(mm) |

1400*3400; 1500*3000; 2000*3000; (Customized size available) |

|||||

| ASTM G65 Procedure A |

0.12 – 0.18g |

|||||

| Operating Temperature |

<400 ℃ |

|||||

| Base Metal Material |

Q235B, Q345B; A36; S235JR and structural steels |

|||||

| Main Industry |

Mining, glass industry, cement plant, steel mill, power plant, etc |

|||||

| Fabrication |

Plasma cutting, Gouging, Countersunk, stud bolt, Bending |

|||||

We can customize the plates in different sizes and thickness based on customer’s drawings. we can also cut, bend and weld the wear plates into specific shapes and parts

Characteristics:

- * Chromium carbide overlay wear resistant plate

* Chemical Composition: C: 3.0-5.0% Cr: 18-30%

* Chromium carbide Cr7C3 volume fraction about 40%

* The thickness of wear resistant layer can reach up to 50 mm

* Heat resistance up to 600°C

* Lager standard wear resistant area 1400*3400mm, 1500*3000mm, 2000*3000mm

* Better flatness with smooth surface

* Hardness: HRC58-65

Note:Carbon and Chromium content varies in different plate.

We also present product or service sourcing and flight consolidation companies. We’ve our own manufacturing unit and sourcing office. We can easily provide you with nearly every form of merchandise similar to our product variety for China OEM China Wear Resistant Material Mining Welding Chromium Carbide Overlay Wear Steel Plate Nm500 Ar500 Alloy Steel Plate Wear Resistant Steel Plate, Our concept would be to assist presenting the confidence of each prospective buyers while using the offering of our most honest service, as well as right merchandise.

China OEM China Steel Plate, Hard 400/500, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you personally.