WD1600 Wear Plates

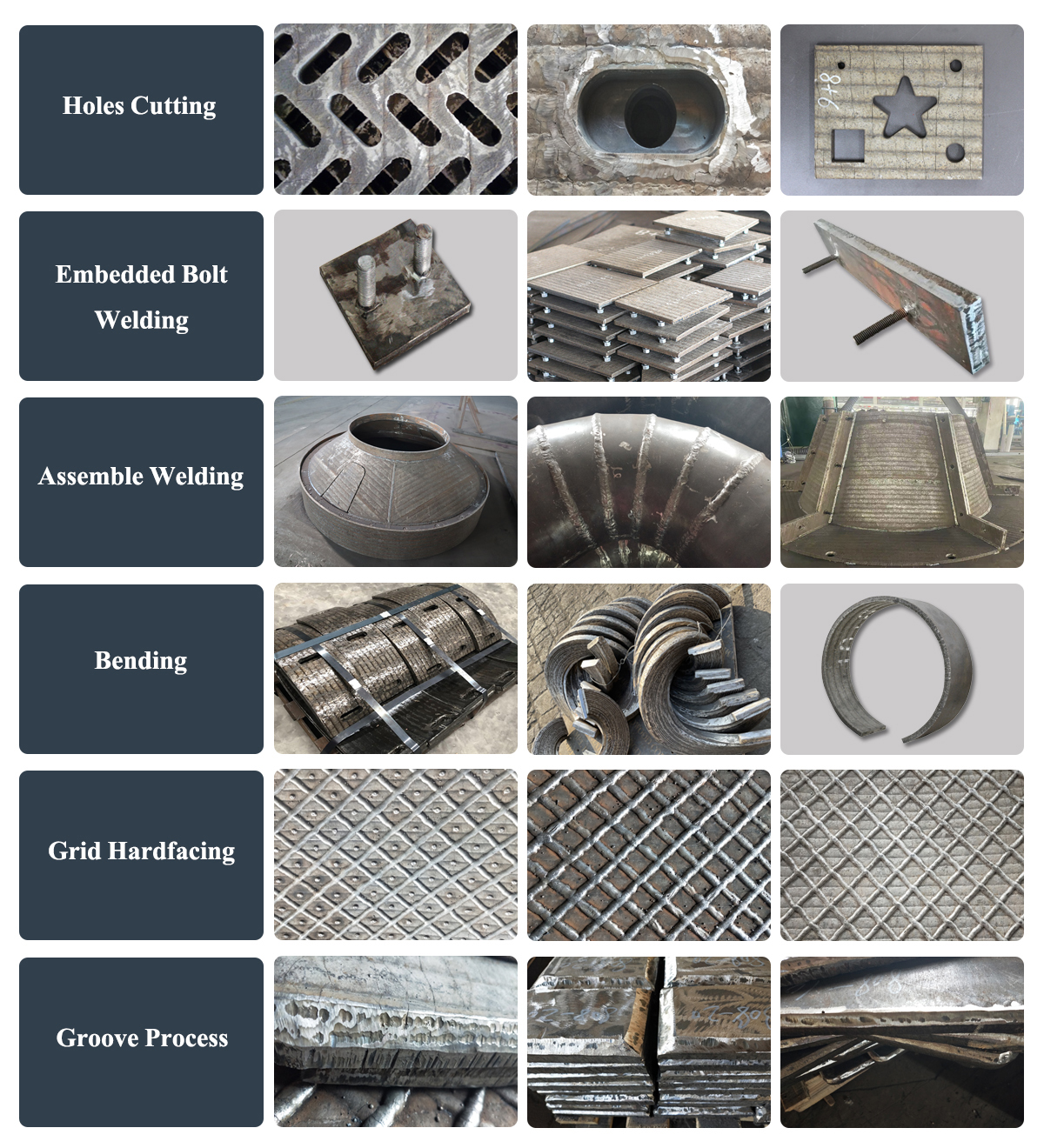

WD1600 is chromium carbide composite cladding fusion bonded to a mild steel backing plate. The deposit has been realized by means of submerged arc welding. WD1600 wear plate is suitable for application involving high abrasion and medium to high impact.

● WD1600 series:

Impact resistant wear plates; Suited for applications involving high abrasion and medium to high impact.

|

Chemicals |

Hardness |

Sheet Size |

Base Metal |

|

C - Cr - Nb - Mo - Fe |

HRC 55-65 |

1400*3500/2100*3500 |

Q235/Q345. etc |

WD1600 is the go-to solution for high-stress areas in:

- Mining & Quarrying: haul truck liners, chute bottoms, impact zones

- Cement Industry: clinker hoppers, cyclone inlets, mixer blades

- Steel & Smelting Plants: ladle chutes, blast furnaces, slag handling

- Power Generation: coal hoppers, ash systems, liners for impact zones

- Heavy Construction Equipment: bucket floors, bulldozer push plates

Note:Carbon and Chromium content varies in different plate.

Write your message here and send it to us