WD1000/1100 Wear Plate

WD1000/WD1100 is chromium carbide composite cladding fusion bonded to a mild steel backing plate. The deposit has been realized by means of flux cored arc welding.

WD1000/WD1100 wear plate is suitable for application involving high abrasion and low to medium impact.

● WD1000/WD1100 series:

Common chromium carbide wear plates produced by flux cored arc welding; Suited for applications involving high abrasion and low to medium impact.

|

Chemicals |

Hardness |

Sheet Size |

Base Metal |

|

C - Cr |

HRC 58-65 |

1400*3500 |

Q235/Q345. etc |

Characteristics:

- * Chromium carbide overlay wear resistant plate

* Chemical Composition: C: 3.0-5.0% Cr: 18-30%

* Chromium carbide Cr7C3 volume fraction about 30%

* The thickness of wear resistant layer can reach up to 50 mm

* Heat resistance up to 600°C

* Lager standard wear resistant area 1400*3500mm, 1500*3000mm, 2000*3000mm

* Better flatness with smooth surface

* Hardness: HRC58-65

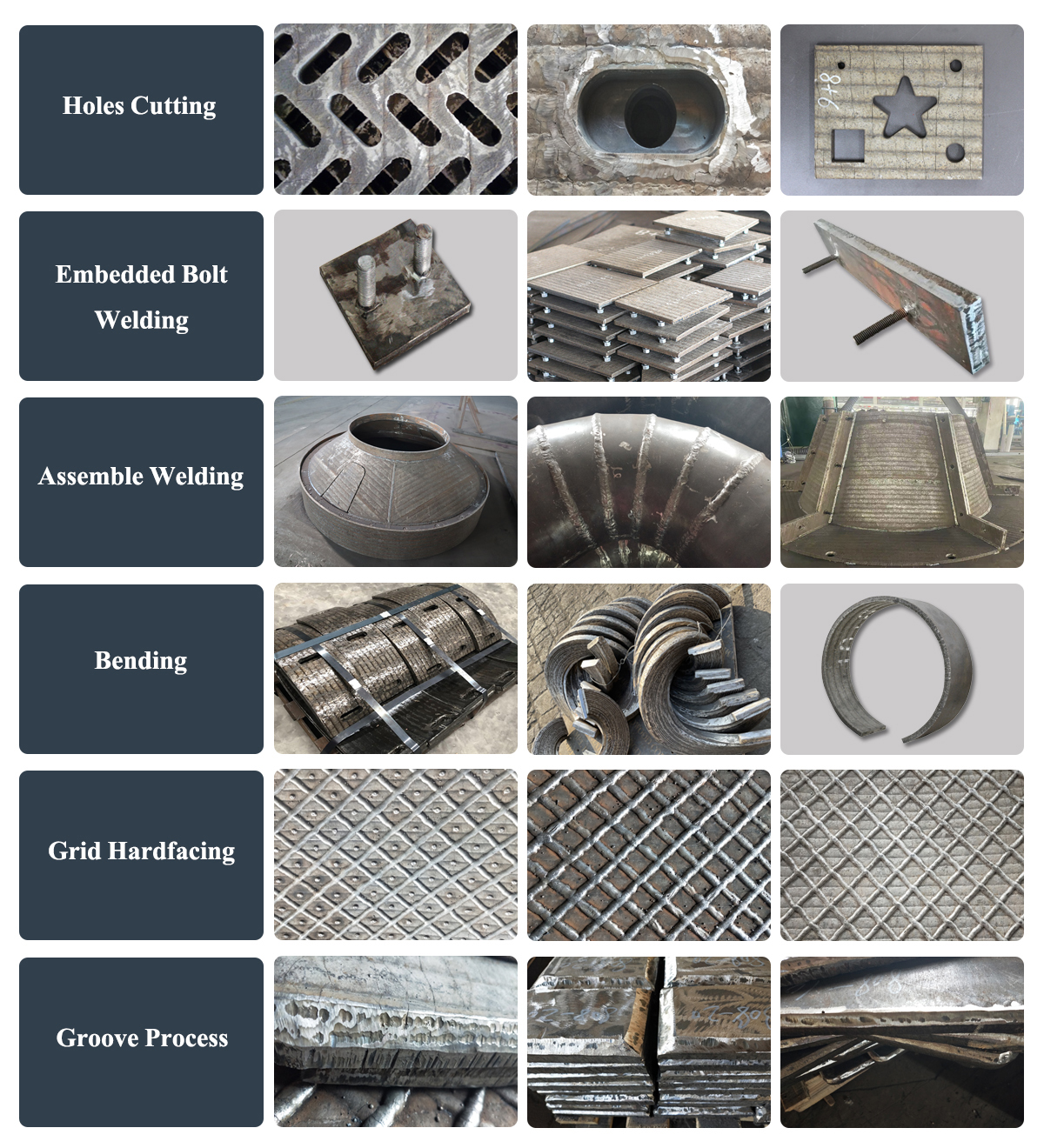

Wear-resistant steel plate customization service - made on demand, accurately matching application scenarios

Customizable content includes:

1.Plate size: supports cutting on demand

2.Thickness range: composite layer thickness 2mm to 50mm, supports multi-layer surfacing

3.Welding processing: supports drawing customization, hole opening, bending, grinding, cutting and other deep processing

4.Heat resistance requirements: customization of special wear-resistant layer under high temperature conditions

Note:Carbon and Chromium content varies in different plate.