Wholesale Price Overlay Wear Plate - WD1000/1100 Wear Plate – Wodon

Wholesale Price Overlay Wear Plate - WD1000/1100 Wear Plate – Wodon Detail:

WD1000/WD1100 series

Abrasion Resistant Chromium Carbide Overlay

WD1000/WD1100 is chromium carbide composite cladding fusion bonded to a mild steel backing plate. The deposit has been realized by means of flux cored arc welding. WD1000/WD1100 wear plate is suitable for application involving high abrasion and low to medium impact.

● WD1000/WD1100 series:

Common chromium carbide wear plates produced by flux cored arc welding; Suited for applications involving high abrasion and low to medium impact.

|

Chemicals |

Hardness |

Sheet Size |

Base Metal |

|

C – Cr – Fe |

HRC 58-63 |

1400*3400 |

Q235/Q345. etc |

| Chemical Composition(%) |

C |

Cr |

Mn |

Si |

Fe |

Other |

|

3.0-5.0 |

15.0-35.0 |

1.0-3.0 |

1.0-3.0 |

Bal. |

- |

|

| Hardness |

HRC 58-65 |

|||||

| Standard Thickness(mm) |

3+3; 4+4; 5+5; 6+4; 6+6; 8+4; 8+6; 8+8; 10+10; 12+12; etc (overlay thickness up to 50mm) |

|||||

| Standard Sheet Size(mm) |

1400*3400; 1500*3000; 2000*3000; (Customized size available) |

|||||

| ASTM G65 Procedure A |

0.12 – 0.18g |

|||||

| Operating Temperature |

<400 ℃ |

|||||

| Base Metal Material |

Q235B, Q345B; A36; S235JR and structural steels |

|||||

| Main Industry |

Mining, glass industry, cement plant, steel mill, power plant, etc |

|||||

| Fabrication |

Plasma cutting, Gouging, Countersunk, stud bolt, Bending |

|||||

Remark:

We can customize the plates in different sizes and thickness based on customer’s drawings. we can also cut, bend and weld the wear plates into specific shapes and parts

Characteristics:

* By open arc welding technology

* Chemical Composition: C: 3.0-4.5% Cr: 15-35%

* Chromium carbide Cr7C3 volume fraction about 40%

* The thickness of wear resistant layer can reach up to 50 mm

* Heat resistance up to 600°C

* Lager standard wear resistant area 1400*3400 mm; 1500*3000 mm; 2000*3000 mm

* Better flatness with smooth surface

Note:Carbon and Chromium content varies in different plate.

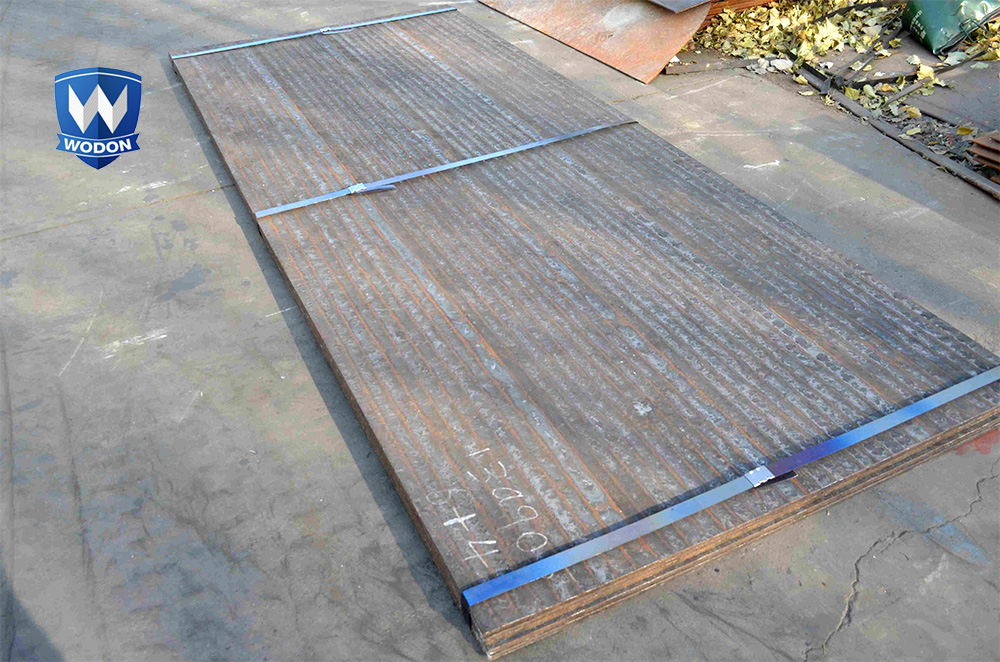

Product detail pictures:

Related Product Guide:

The incredibly abundant projects administration experiences and 1 to one provider model make the superior importance of small business communication and our easy understanding of your expectations for Wholesale Price Overlay Wear Plate - WD1000/1100 Wear Plate – Wodon , The product will supply to all over the world, such as: Spain, Istanbul, Uruguay, Qualified R&D engineer might be there for your consultation service and we will try our best to meet your requirements. So you should feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we are going to surely present you with the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we'll make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we're here to welcome your inquiries for any of our merchandise and service.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.