High Quality Chromium Carbide Overlay Wear Plate - WD1000/1100 Wear Plate – Wodon

High Quality Chromium Carbide Overlay Wear Plate - WD1000/1100 Wear Plate – Wodon Detail:

WD1000/WD1100 series

Abrasion Resistant Chromium Carbide Overlay

WD1000/WD1100 is chromium carbide composite cladding fusion bonded to a mild steel backing plate. The deposit has been realized by means of flux cored arc welding. WD1000/WD1100 wear plate is suitable for application involving high abrasion and low to medium impact.

● WD1000/WD1100 series:

Common chromium carbide wear plates produced by flux cored arc welding; Suited for applications involving high abrasion and low to medium impact.

|

Chemicals |

Hardness |

Sheet Size |

Base Metal |

|

C – Cr – Fe |

HRC 58-63 |

1400*3400 |

Q235/Q345. etc |

| Chemical Composition(%) |

C |

Cr |

Mn |

Si |

Fe |

Other |

|

3.0-5.0 |

15.0-35.0 |

1.0-3.0 |

1.0-3.0 |

Bal. |

- |

|

| Hardness |

HRC 58-65 |

|||||

| Standard Thickness(mm) |

3+3; 4+4; 5+5; 6+4; 6+6; 8+4; 8+6; 8+8; 10+10; 12+12; etc (overlay thickness up to 50mm) |

|||||

| Standard Sheet Size(mm) |

1400*3400; 1500*3000; 2000*3000; (Customized size available) |

|||||

| ASTM G65 Procedure A |

0.12 – 0.18g |

|||||

| Operating Temperature |

<400 ℃ |

|||||

| Base Metal Material |

Q235B, Q345B; A36; S235JR and structural steels |

|||||

| Main Industry |

Mining, glass industry, cement plant, steel mill, power plant, etc |

|||||

| Fabrication |

Plasma cutting, Gouging, Countersunk, stud bolt, Bending |

|||||

We can customize the plates in different sizes and thickness based on customer’s drawings. we can also cut, bend and weld the wear plates into specific shapes and parts

Characteristics:

- * Chromium carbide overlay wear resistant plate

* Chemical Composition: C: 3.0-5.0% Cr: 18-30%

* Chromium carbide Cr7C3 volume fraction about 40%

* The thickness of wear resistant layer can reach up to 50 mm

* Heat resistance up to 600°C

* Lager standard wear resistant area 1400*3400mm, 1500*3000mm, 2000*3000mm

* Better flatness with smooth surface

* Hardness: HRC58-65

Note:Carbon and Chromium content varies in different plate.

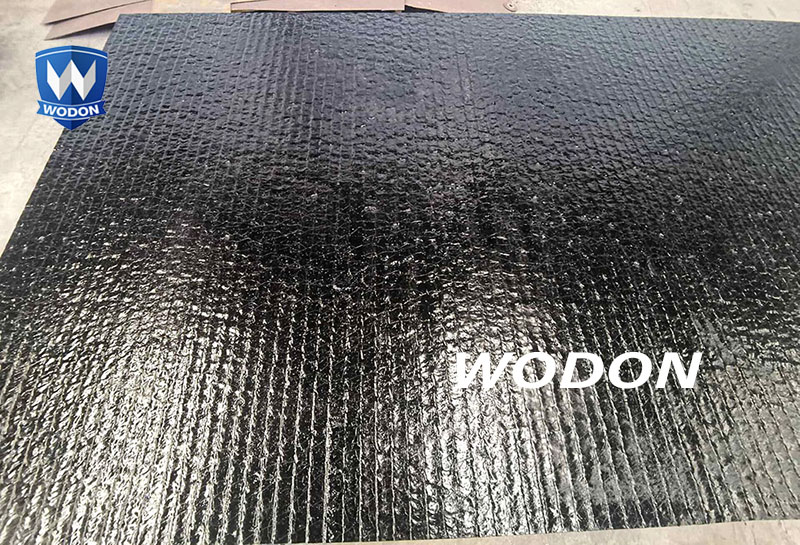

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for High Quality Chromium Carbide Overlay Wear Plate - WD1000/1100 Wear Plate – Wodon , The product will supply to all over the world, such as: Gabon, Nigeria, belarus, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers,and establish a long term win-win business relationship. For more information,please contact us. And it's our great pleasure if you like to have a personally meeting in our office.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.