-

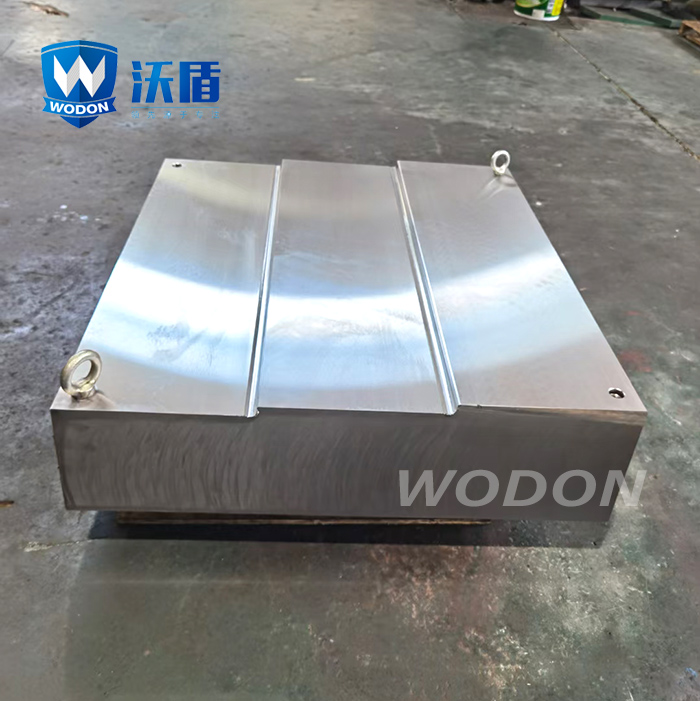

Composite Chromium Carbide Overlay Hardfacing Wear Resistant Plate

Composite Chromium Carbide Overlay Hardfacing Wear Resistant Plate -

Composite Chromium Carbide Clad Mining Bimetallic Wear Plates Liner

Composite Chromium Carbide Clad Mining Bimetallic Wear Plates Liner -

Custom Sizes Bimetal Composite Clad Chromium Carbide Wear Plate

Custom Sizes Bimetal Composite Clad Chromium Carbide Wear Plate -

Bimetal Anti-Wear 5+5 Chromium Carbide Overlay Wear Plate

Bimetal Anti-Wear 5+5 Chromium Carbide Overlay Wear Plate -

WD1000/1100 Wear Plate

WD1000/1100 Wear Plate -

WD1200/1500 Wear Plate

WD1200/1500 Wear Plate -

WD1600 Wear Plates

WD1600 Wear Plates -

WD1800 Wear Plates

WD1800 Wear Plates -

WD2000 Wear Plates

WD2000 Wear Plates -

WD-NC100 Wear Plate

WD-NC100 Wear Plate -

Steel Mill

Steel Mill -

WD-M3 Smooth surface

WD-M3 Smooth surface -

Powper

Powper -

Mining

Mining -

Cement Plants

Cement Plants

- Tianjin Wodon Wear Resistant Material Co., Ltd.

- cs@chinawodon.com

- 0086 22 86897973