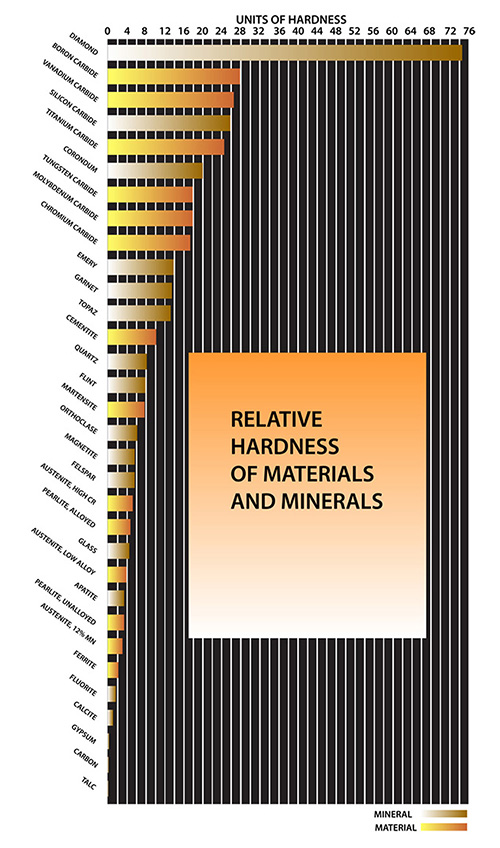

Relative hardness of Materials and Minerals

-

- 1. Diamond

- 2. Boron carbide

- 3. Vanadium carbide

- 4. Silicon carbide

- 5. Titanium carbide

- 6. Corundum

- 7. Tungsten carbide

- 8. Molybdenum carbide

- 9. Chromium carbide

- 10. Emery

- 11. Garnet

- 12. Topaz

- 13. Cementite

- 14. Quartz

- 15. Flint

- 16. Martensite

- 17. Orthoclase

- 18. Magnetite

- 19. Felspar

- 20. Austenite, High CR

- 21. Pearlite, Alloyed

- 22. Glass

- 23. Austenite, Low alloy

- 24. Apatite

- 25. Pearlite, Unalloyed

- 26. Austenite, 12% Mn

- 27. Ferrite

- 28. Fluorite

- 29. Calcite

- 30. Gypsum

- 31. Carbon

- 32. Talc

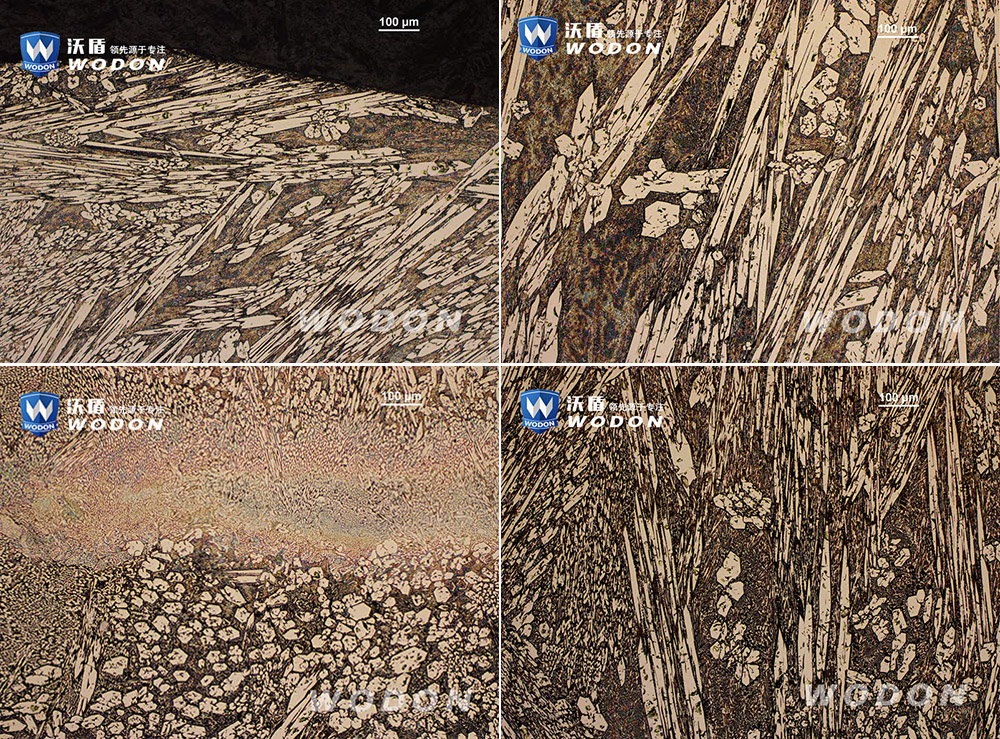

- Wodon are specialized in produce Chromium carbide overlay wear plate, we adopt submerged arc welding technoloy which contains more Cr content ranging from 25% to 45%. the carbide volume fraction on the microstructure is above 50% and maximum hardness of hard particle is HV1800. the ASTM-G65 methode A is under 0.16g.

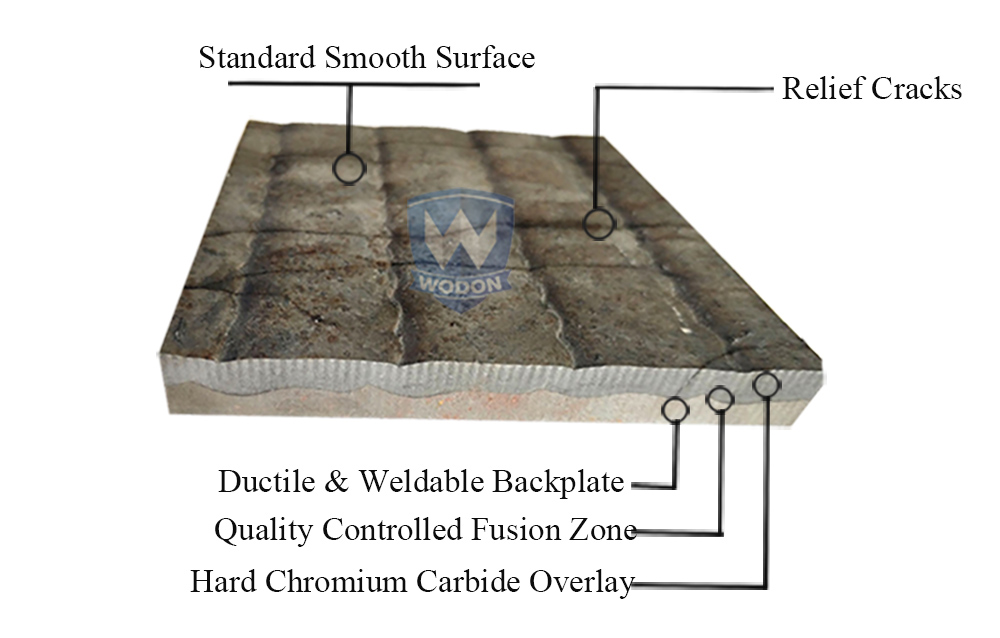

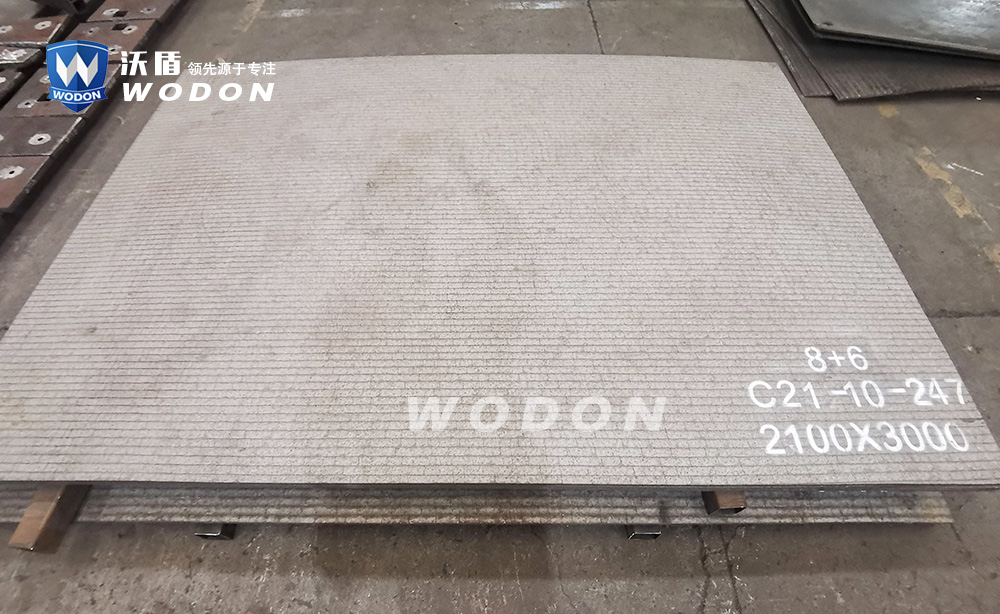

- Chromium Carbide bimetallic plate:

- Medium/Low carbon steel + Abrasion resistant layers → Chromium carbide bimetallic plate with metallurgical bonding

- (Q235/Q345B + Chromium Carbide overlay → Chromium carbide bimetallic plate by Submerged arc or Open arc welding

- technology)

- Detail:

- The wear resistant layer has a high amount of chromium carbide hard particles. These particles are distributed evenly throughout the layer, creating a strong microstructure. The hardness is HRC 58~65 and depends on the overlay's thickness.

- The main ingredients of Wodon plate are C(%): 3.0~6.0 and Cr(%): 25~45. This chemical proportion results in a large amount of Cr7C3 chrome carbide hard particles. The micro-hardness (up to HV1800) of these particles throughout the layer will guarantee a super wear resistant surface.

- The overlay and base plate are metallurgical bonding. The overlay will penetrate into base plate about 0.8~1.8 mm, reaching up to 350 Mpa in our tests.

-

- WD1200 wear plate can be used for severe abrasion applications.

- * Chromium carbide overlay wear resistant plate

- * By submerged arc welding technology

- * Chemical Composition: C: 3.0-6.0% Cr: 25-45%

- * Chromium carbide Cr7C3 volume fraction about 50%

- * The thickness of wear resistant layer can reach up to 50 mm

- * Heat resistance up to 600°C

- * Lager standard wear resistant area 1400*3000mm, 1400*3500mm, 2100*3500mm

- * Better flatness with smooth surface

- * Hardness: HRC58-65 (650-720HV)

- These plates are widely used in Mining, Cement, Power, Coal, Port, Wind turbines and Metallurgical industry.

-

Post time: Sep-27-2021