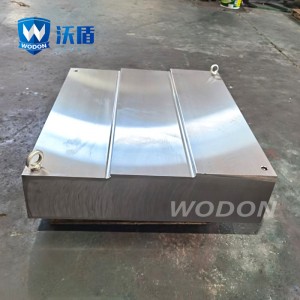

Composite Chromium Carbide Clad Mining Bimetallic Wear Plates Liner

Composite Chromium Carbide Clad Mining Bimetallic Wear Plates Liner

- Surface hardness: HRC 58-65

- Alloy composition:C: 3-5%,Cr: 18-30%

- Customizable thickness: base plate 2-50mm, cladding layer 2-50mm

The low-carbon steel substrate provides good mechanical strength and structural stability, and the high-chromium carbide cladding layer ensures excellent wear and corrosion resistance.

It is suitable for typical wear parts such as ore loading and unloading, belt transfer, silo lining, conveying system, screening equipment, etc., and is suitable for various high-impact and high-friction working conditions.

From an operational perspective, the total cost of wear parts is not only reflected in the purchase cost, but also in the replacement frequency, downtime loss, and wear cost per unit of output material. Compared with traditional wear-resistant steel plates (such as NM400/NM500), the wear life of this product is increased by 3~5 times, significantly reducing the replacement frequency and equipment downtime.