Super Lowest Price Carbide Overlay Plate - WD1000/1100 Wear Plate – Wodon

Super Lowest Price Carbide Overlay Plate - WD1000/1100 Wear Plate – Wodon Detail:

WD1000/WD1100 series

Abrasion Resistant Chromium Carbide Overlay

WD1000/WD1100 is chromium carbide composite cladding fusion bonded to a mild steel backing plate. The deposit has been realized by means of flux cored arc welding. WD1000/WD1100 wear plate is suitable for application involving high abrasion and low to medium impact.

● WD1000/WD1100 series:

Common chromium carbide wear plates produced by flux cored arc welding; Suited for applications involving high abrasion and low to medium impact.

|

Chemicals |

Hardness |

Sheet Size |

Base Metal |

|

C – Cr – Fe |

HRC 58-63 |

1400*3400 |

Q235/Q345. etc |

| Chemical Composition(%) |

C |

Cr |

Mn |

Si |

Fe |

Other |

|

3.0-5.0 |

15.0-35.0 |

1.0-3.0 |

1.0-3.0 |

Bal. |

- |

|

| Hardness |

HRC 58-65 |

|||||

| Standard Thickness(mm) |

3+3; 4+4; 5+5; 6+4; 6+6; 8+4; 8+6; 8+8; 10+10; 12+12; etc (overlay thickness up to 50mm) |

|||||

| Standard Sheet Size(mm) |

1400*3400; 1500*3000; 2000*3000; (Customized size available) |

|||||

| ASTM G65 Procedure A |

0.12 – 0.18g |

|||||

| Operating Temperature |

<400 ℃ |

|||||

| Base Metal Material |

Q235B, Q345B; A36; S235JR and structural steels |

|||||

| Main Industry |

Mining, glass industry, cement plant, steel mill, power plant, etc |

|||||

| Fabrication |

Plasma cutting, Gouging, Countersunk, stud bolt, Bending |

|||||

Remark:

We can customize the plates in different sizes and thickness based on customer’s drawings. we can also cut, bend and weld the wear plates into specific shapes and parts

Characteristics:

* By open arc welding technology

* Chemical Composition: C: 3.0-4.5% Cr: 15-35%

* Chromium carbide Cr7C3 volume fraction about 40%

* The thickness of wear resistant layer can reach up to 50 mm

* Heat resistance up to 600°C

* Lager standard wear resistant area 1400*3400 mm; 1500*3000 mm; 2000*3000 mm

* Better flatness with smooth surface

Note:Carbon and Chromium content varies in different plate.

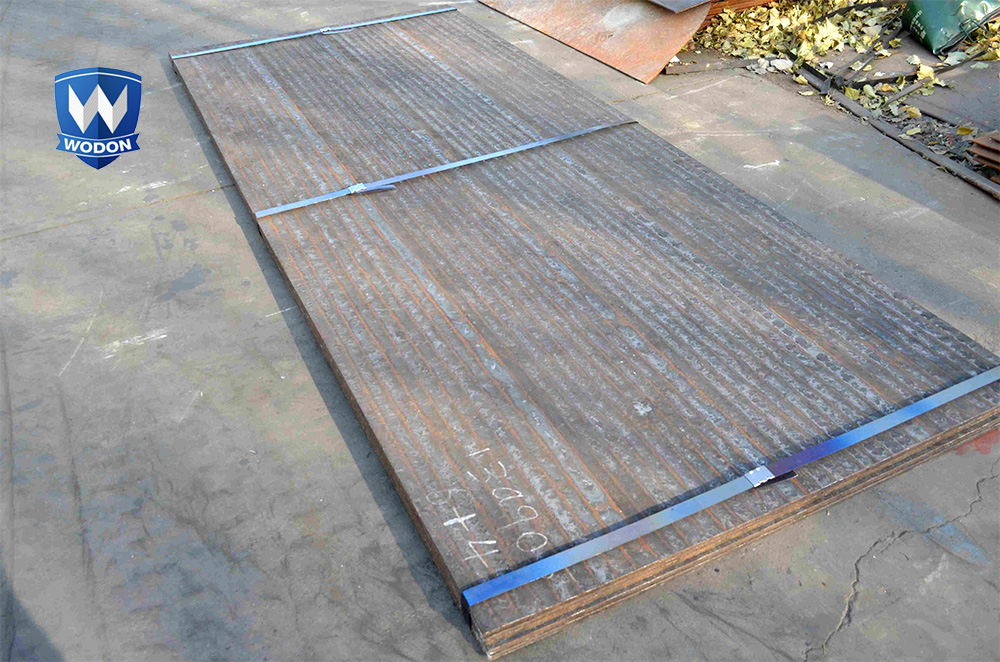

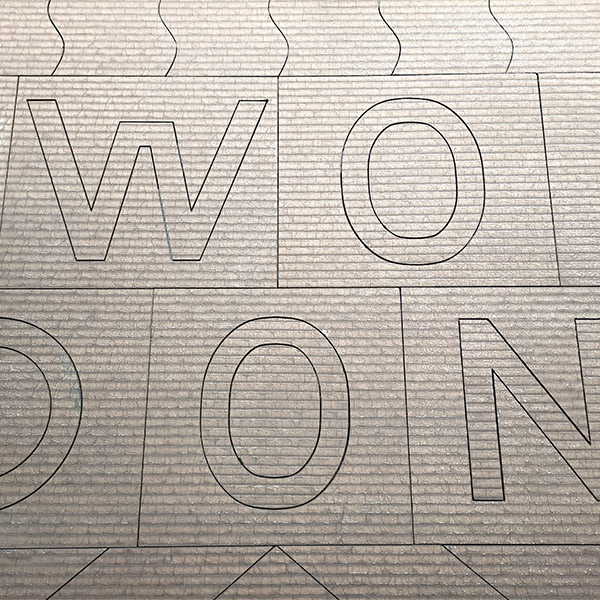

Product detail pictures:

Related Product Guide:

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we're much more specialist and extra hard-working and do it in cost-effective way for Super Lowest Price Carbide Overlay Plate - WD1000/1100 Wear Plate – Wodon , The product will supply to all over the world, such as: Mombasa, Salt Lake City, Hungary, To win customers' confidence, Best Source has set up a strong sales and after-sales team to deliver the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.