Short Lead Time for Hammer Plate Hardfacing - WD-M3 Smooth surface – Wodon

Short Lead Time for Hammer Plate Hardfacing - WD-M3 Smooth surface – Wodon Detail:

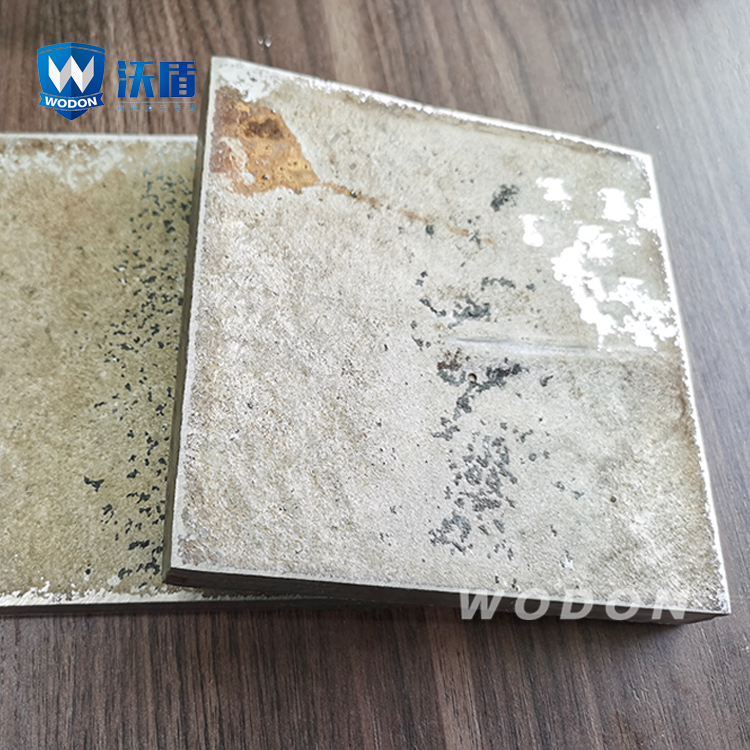

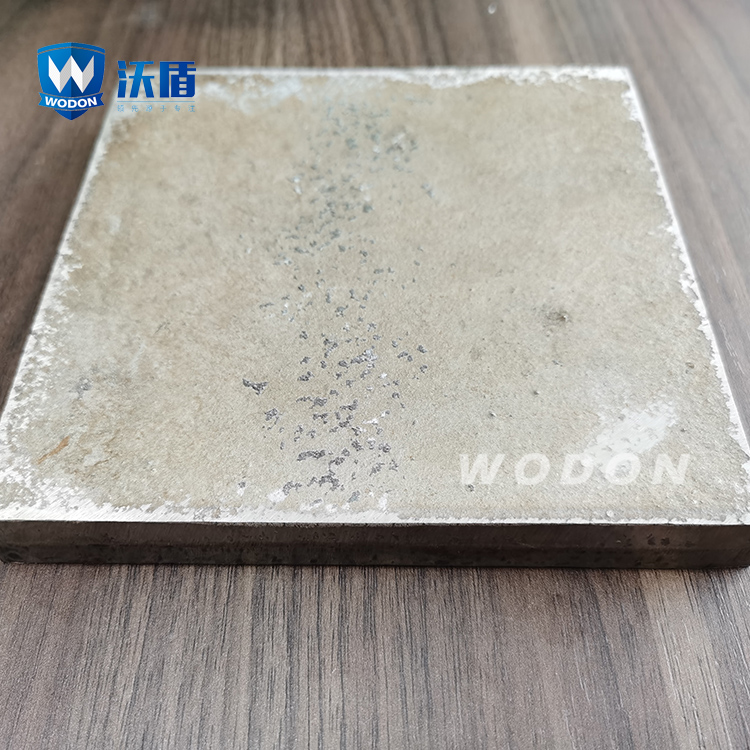

Smooth Surface

Chromium Carbide Overlay Plate

ADVANTAGE:

* Smooth surface, single pass overlay, No surface weld beads

* Consistent microstructure and hardness down to fusion line

* Low friction co-efficient

* Excellent abrasion and impact resistant properties

* Operating temperature <600℃

* Optional in unique non-magnetic overlay

* Available in mill and pre-polished surface finish

TYPICAL TECHNICAL STANDARD

|

Grade |

Chemical composition |

|||||||

|

|

C |

Cr |

Mn |

Si |

B |

S |

P |

Nb+Mo+Ti+V+W |

|

WD-M3 |

2.0-5.0 |

18-35 |

<1.5 |

<1.2 |

<0.6 |

<0.033 |

<0.033 |

<1.5 |

|

WD-M7 |

2.0-5.0 |

18-28 |

<1.5 |

<1.2 |

<0.4 |

<0.033 |

<0.033 |

7-10 |

| Basic Elements |

WD-M3 |

WD-M7 |

| Base material |

Q235B |

Q235B |

| Main alloy hard phase |

Chromium carbide |

Chromium carbide + Composite carbide |

| Primary carbide volume (%) |

>37 |

>37 |

| Overlay Hardness by HV (HRC) |

670 (58) |

670 (58) |

| Rubber weheel abrasion test with dry sand (g) |

<0.15g |

<0.14g |

| Impact abrasion test (g) |

<0.10g |

<0.08g |

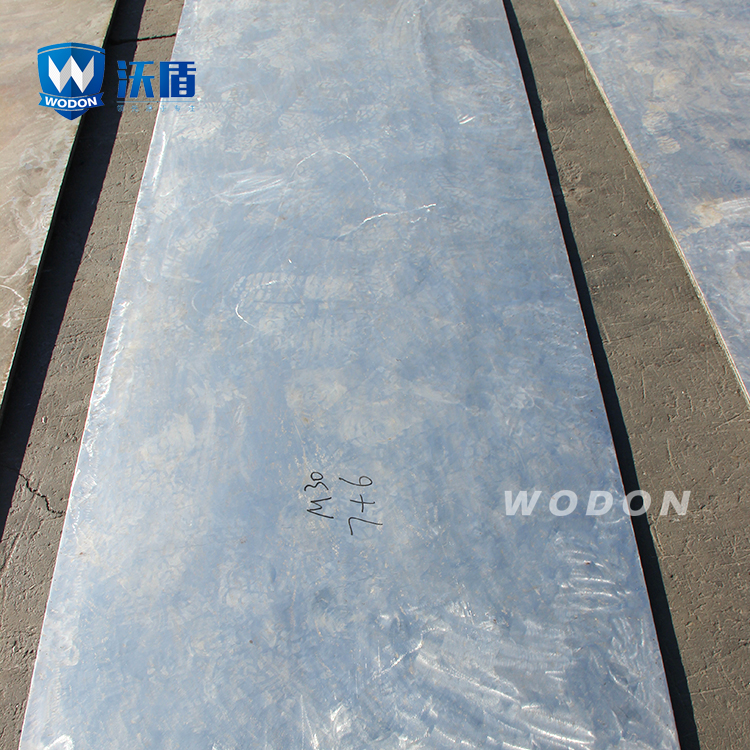

| Standard thickness (mm) |

5/5, 6/7, 8/9, 10/11, 12/11, 17/11 |

17/11, 20/11, 24/13 |

| Standard plate size (mm) |

1000*3000, 600*3000 |

600*3000 |

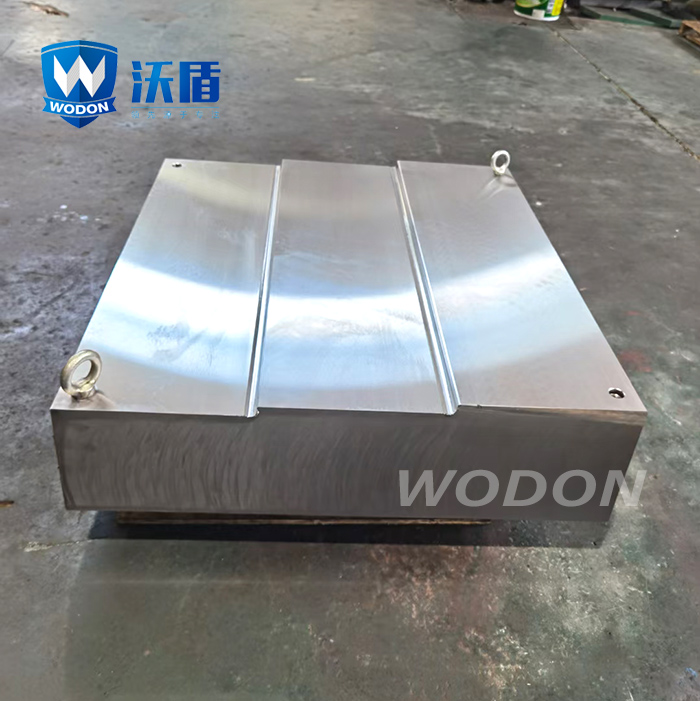

| Recommended application |

Common abrasion |

Extreme abrasion |

Product detail pictures:

Related Product Guide:

We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We intention to create extra worth for our buyers with our prosperous resources, superior machinery, experienced workers and superb services for Short Lead Time for Hammer Plate Hardfacing - WD-M3 Smooth surface – Wodon , The product will supply to all over the world, such as: venezuela, Bogota, Juventus, As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we are not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and provide instant communication. You will instantly feel our expertise and attentive service.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.