What You Need to Know About Pipe Hardfacing

Pipe hardfacing is often selected to solve wear problems, but many projects fail to achieve the expected service life due to unclear specification rather than material quality.

From a user’s perspective, understanding a few key principles can significantly improve performance and cost control.

1. Identify Where the Wear Occurs

Before choosing any alloy, the first question is simple:

Is the wear internal or external?

Internal hardfacing is used for material transport, where flow velocity, particle impact, and buildup matter.

External hardfacing protects pipes from outside abrasion or sliding contact.

2. Pipe Geometry Matters as Much as Material

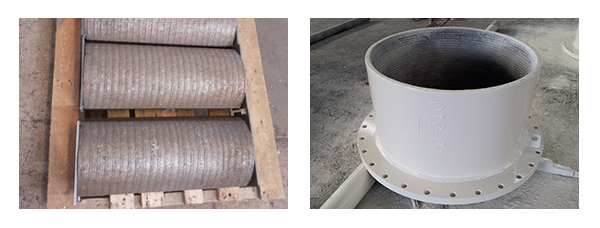

Chromium carbide overlay pipes are not standard pipes with a coating added.

Their performance depends heavily on pipe type:

Straight pipes require clear definition of finished diameter and length.

Reducers must specify both inlet and outlet sizes.

Elbows are the most critical components and typically fail first if poorly designed.

For elbows, the diameter, bend radius, and angle are essential. Without them, no reliable hardfacing solution exists.

3. Finished Dimensions Must Be Clear

After hardfacing, the original pipe dimensions change.

For this reason, customers should always specify:

Whether the dimension refers to the inner diameter or the outer diameter

Finished size after hardfacing, not base pipe size

Whether pipe sections can be spliced or must be one piece

Ambiguous dimensions often lead to a mismatched installation.

When wear location, geometry, and finished dimensions are properly specified, hardfacing becomes a reliable and predictable solution.

For technical support, specifications, or quotations, please reach out: cs@chinawodon.com

Post time: Feb-03-2026