Inside the Manufacturing Process of Flux Cored Wire: Key Problems and Proven Fixes

The Rise of Flux Core Welding Wire

In recent years, flux core welding wire has emerged as a preferred choice across industries such as shipbuilding, steel structures, mining, and heavy equipment manufacturing. Its rapid rise is driven by the demand for high-efficiency, cost-effective, and adaptable welding solutions.

Compared to solid wire or traditional stick electrodes, flux cored wire offers higher deposition rates, improved weld quality, and excellent performance in all welding positions. These benefits make it especially valuable in large-scale fabrication where speed and strength are critical.

Core Advantages of Flux Core Welding Wire

The continued popularity of flux core welding wire is rooted in several technical advantages:

High welding efficiency: Productivity is up to 3–5 times that of traditional electrodes.

All-position capability: Suitable for vertical, horizontal, and overhead welds.

Lower spatter and cleaner welds: Particularly with low spatter flux core wire, which reduces post-weld cleanup time.

Customizable formulations: The ability to tailor core ingredients allows for specialized wires meeting specific metallurgical requirements.

Cost-effectiveness: The overall welding cost is significantly reduced due to higher efficiency and lower material waste.

Key Challenges in Wire Manufacturing

Despite its advantages, the production of flux cored wire poses several technical challenges that can affect product quality and consistency:

Uneven powder distribution: Powder shifting during rolling can result in hollow sections or weak welds.

Weak mechanical integrity: Insufficient filling or poorly formed seams can cause wire collapse, leakage, or breakage.

Surface defects and porosity: Often linked to contamination or inconsistencies in core composition.

Frequent breakage during drawing: Typically due to improper tension, excessive work hardening, or roller misalignment.

Process Optimization Strategies

To address these production bottlenecks, manufacturers must focus on a combination of equipment upgrades, material handling, and process control.

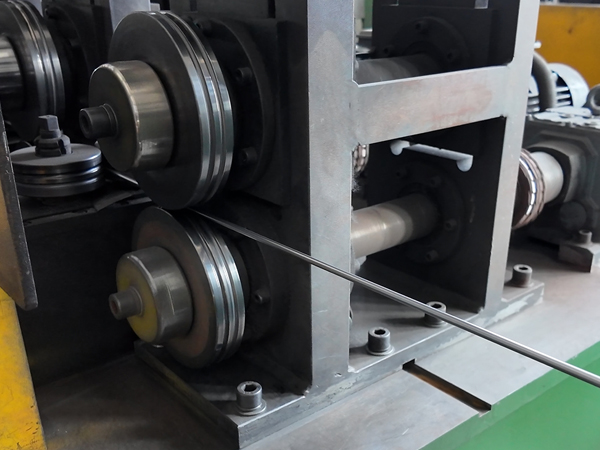

Equipment Calibration and Roller Configuration

Proper alignment of forming rollers is essential to ensure the seam remains straight and well-sealed. Misaligned rollers may lead to helical seams or excessive twisting, resulting in powder leakage or wire deformation. Roller gap and compression sequence must be calibrated for gradual reduction to preserve wire integrity.

Core Powder Quality and Handling

The flow characteristics of core powder are critical. Particle size, shape, and purity influence fill consistency and alloying behavior. Overly fine powder may reduce flowability, while coarse particles can lead to segregation. For low spatter flux core wire, maintaining alloy uniformity is essential to minimize oxidation and improve weld appearance.

Cleaning and Pre-Treatment of Steel Strip

Before forming, the steel strip must be free of oil and contaminants. Residual grease can be trapped inside the wire, causing gas porosity or even cold cracks during welding. Ultrasonic cleaning is a highly effective method, using cavitation forces to dislodge particles and ensure a clean surface.

Optimal Fill Rate Management

The fill rate—the proportion of powder to total wire mass—must be tightly controlled. A low fill rate results in underfilled wires that are prone to collapsing, while a high fill rate increases the risk of leakage and creates difficulty in sealing the seam. Balancing fill rate is essential to ensure weld consistency and mechanical performance.

Wire Compression Ratio and Work Hardening

High compression during forming leads to work hardening, increasing the tensile strength but reducing ductility. This makes the wire more susceptible to fracture in later stages. Using roller dies instead of fixed molds in early drawing passes helps alleviate internal stresses and preserves ductility.

Drawing Force and Speed Control

The drawing process must balance pulling force and speed. Excessive drawing force caused by high compression or improper die geometry can result in sudden wire breakage. A gradual acceleration strategy—starting at low speed—helps reduce tension peaks and promotes uniform deformation.

Practical Recommendations & Welding Tips

To maximize performance in the field, here are some practical flux core wire welding tips:

For stainless steel flux core wire, pre-clean surfaces thoroughly and use DCEN (Direct Current Electrode Negative) where applicable.

Use proper contact tip size to avoid feeding issues, especially with hardfacing flux cored wire.

Store wires in dry, temperature-controlled environments to prevent moisture contamination.

Adjust voltage and wire feed rate for different positions to maintain arc stability and penetration.

Post time: Jun-23-2025