Hot-selling Crc Wear Plate - WD-M3 Smooth surface – Wodon

Hot-selling Crc Wear Plate - WD-M3 Smooth surface – Wodon Detail:

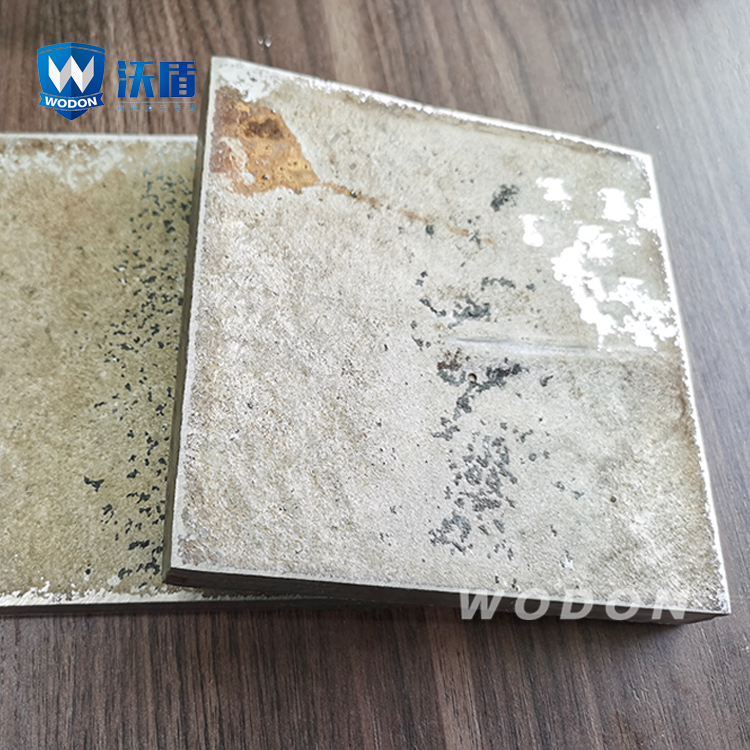

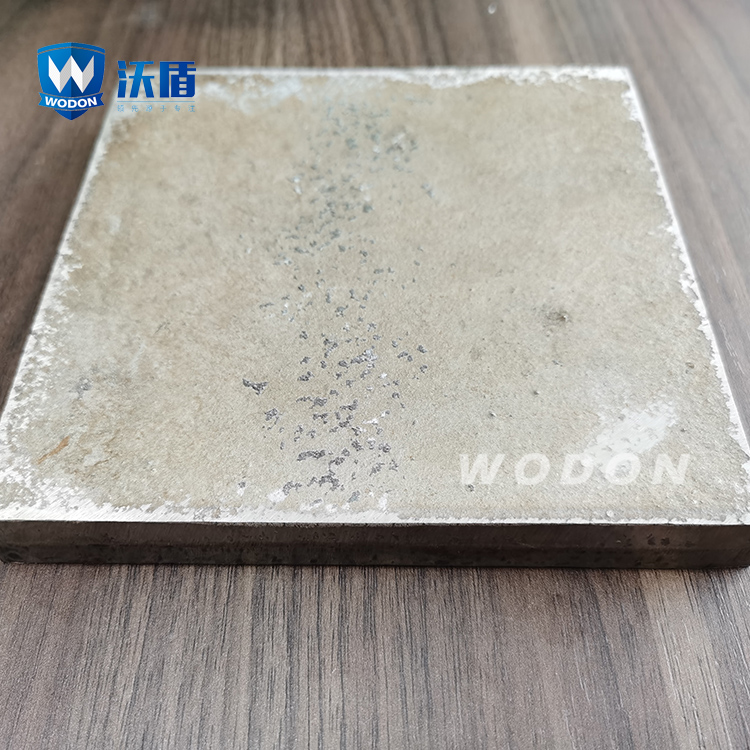

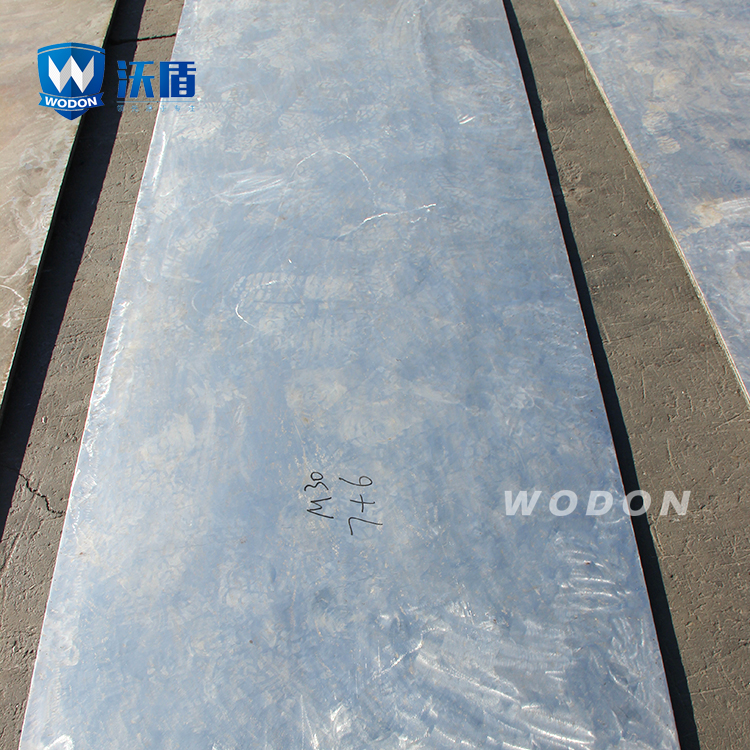

Smooth Surface

Chromium Carbide Overlay Plate

ADVANTAGE:

* Smooth surface, single pass overlay, No surface weld beads

* Consistent microstructure and hardness down to fusion line

* Low friction co-efficient

* Excellent abrasion and impact resistant properties

* Operating temperature <600℃

* Optional in unique non-magnetic overlay

* Available in mill and pre-polished surface finish

TYPICAL TECHNICAL STANDARD

|

Grade |

Chemical composition |

|||||||

|

|

C |

Cr |

Mn |

Si |

B |

S |

P |

Nb+Mo+Ti+V+W |

|

WD-M3 |

2.0-5.0 |

18-35 |

<1.5 |

<1.2 |

<0.6 |

<0.033 |

<0.033 |

<1.5 |

|

WD-M7 |

2.0-5.0 |

18-28 |

<1.5 |

<1.2 |

<0.4 |

<0.033 |

<0.033 |

7-10 |

| Basic Elements |

WD-M3 |

WD-M7 |

| Base material |

Q235B |

Q235B |

| Main alloy hard phase |

Chromium carbide |

Chromium carbide + Composite carbide |

| Primary carbide volume (%) |

>37 |

>37 |

| Overlay Hardness by HV (HRC) |

670 (58) |

670 (58) |

| Rubber weheel abrasion test with dry sand (g) |

<0.15g |

<0.14g |

| Impact abrasion test (g) |

<0.10g |

<0.08g |

| Standard thickness (mm) |

5/5, 6/7, 8/9, 10/11, 12/11, 17/11 |

17/11, 20/11, 24/13 |

| Standard plate size (mm) |

1000*3000, 600*3000 |

600*3000 |

| Recommended application |

Common abrasion |

Extreme abrasion |

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and exceptional good quality manage throughout all stages of production enables us to guarantee total shopper satisfaction for Hot-selling Crc Wear Plate - WD-M3 Smooth surface – Wodon , The product will supply to all over the world, such as: Lahore, Macedonia, California, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we have been going to have a bright prospect and to be distributed all over the world in the years to come.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!