High Quality Wear Plate Welding Wire - Roller Repairing Hardfacing Wires – Wodon

High Quality Wear Plate Welding Wire - Roller Repairing Hardfacing Wires – Wodon Detail:

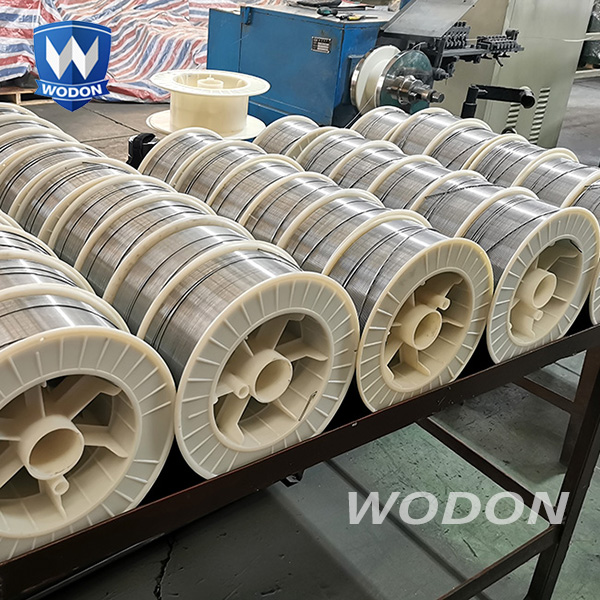

Vertical Roller Hardfacing welding wire

| Application | Model | hardness | Spec (mm) | Main Ingredients |

| Suitable for repairing coal grinding mill, grinding disc, cement vertical mill, etc. | HB100 | 58-63 | 2.8, 3.2 | C, Cr, Mo |

| HB100L+ | 58-63 | 2.8, 3.2 | C, Cr, Mo | |

| HB100+ | 58-63 | 2.8, 3.2 | C, Cr, Mo | |

| HB350 | 58-63 | 2.8, 3.2 | C, Cr, Mo, Nb | |

| HB650 | 58-63 | 2.8, 3.2 | C, Cr, Mo, Nb |

Squeeze Roller Hardfacing welding wire

| Application | Model | Diameter [mm] | Hardness [HRC] | Main Ingredient |

| Suitable for base layer | HB-JYG1# | 2.8 | - | C, Cr, Mo |

| Suitable for buffer layer | HB-JYG2# | 2.8 | 55-63 | C, Cr, Mo |

| Suitable for pattern layer | HB-JYG3# | 2.8 | 55-63 | C, Cr, Mo |

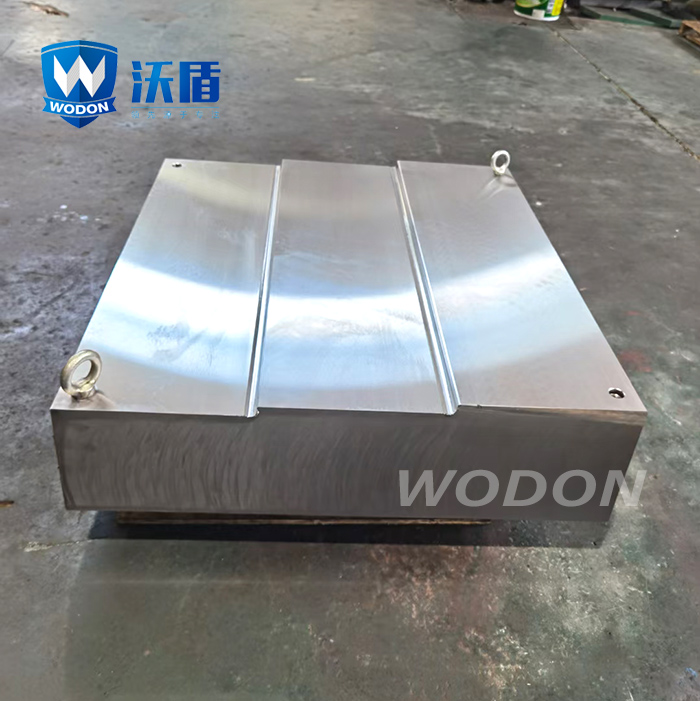

Product detail pictures:

Related Product Guide:

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for High Quality Wear Plate Welding Wire - Roller Repairing Hardfacing Wires – Wodon , The product will supply to all over the world, such as: Victoria, British, kazakhstan, With a team of experienced and knowledgeable personnel, our market covers South America, the USA, the Mid East, and North Africa. Many customers have become our friends after good cooperation with us. If you have the requirement for any of our products, please contact us now. We are looking forward to hearing from you soon.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

Write your message here and send it to us