Good Quality Hardfacing Wires - Roller Repairing Hardfacing Wires – Wodon

Good Quality Hardfacing Wires - Roller Repairing Hardfacing Wires – Wodon Detail:

Vertical Roller Hardfacing welding wire

| Application | Model | hardness | Spec (mm) | Main Ingredients |

| Suitable for repairing coal grinding mill, grinding disc, cement vertical mill, etc. | HB100 | 58-63 | 2.8, 3.2 | C, Cr, Mo |

| HB100L+ | 58-63 | 2.8, 3.2 | C, Cr, Mo | |

| HB100+ | 58-63 | 2.8, 3.2 | C, Cr, Mo | |

| HB350 | 58-63 | 2.8, 3.2 | C, Cr, Mo, Nb | |

| HB650 | 58-63 | 2.8, 3.2 | C, Cr, Mo, Nb |

Squeeze Roller Hardfacing welding wire

| Application | Model | Diameter [mm] | Hardness [HRC] | Main Ingredient |

| Suitable for base layer | HB-JYG1# | 2.8 | - | C, Cr, Mo |

| Suitable for buffer layer | HB-JYG2# | 2.8 | 55-63 | C, Cr, Mo |

| Suitable for pattern layer | HB-JYG3# | 2.8 | 55-63 | C, Cr, Mo |

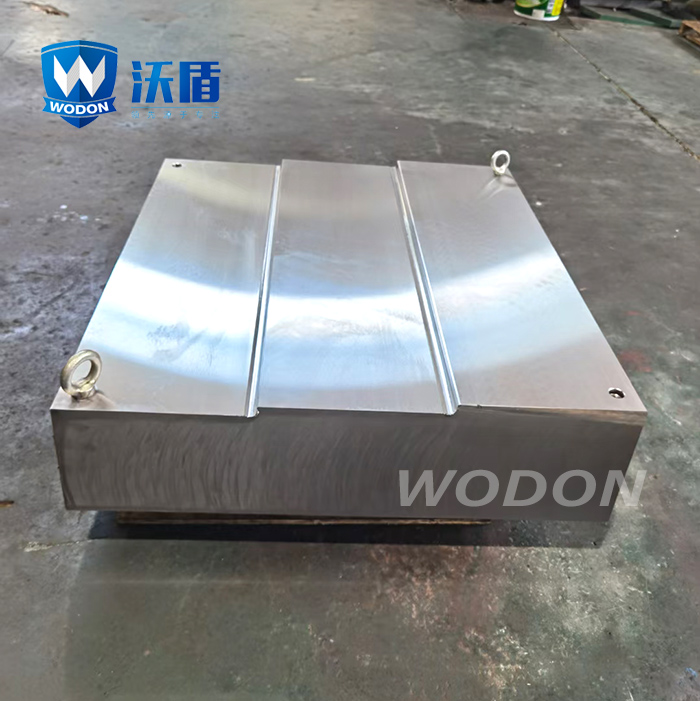

Product detail pictures:

Related Product Guide:

Adhering into the theory of "quality, services, efficiency and growth", now we have gained trusts and praises from domestic and international shopper for Good Quality Hardfacing Wires - Roller Repairing Hardfacing Wires – Wodon , The product will supply to all over the world, such as: Palestine, venezuela, Salt Lake City, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.

Write your message here and send it to us