Free sample for Wear Plate Steel - WD1200/1500 Wear Plate – Wodon

Free sample for Wear Plate Steel - WD1200/1500 Wear Plate – Wodon Detail:

WD1200/WD1500 series

Abrasion Resistant Chromium Carbide Overlay

WD1200/WD1500 is chromium carbide composite cladding fusion bonded to a mild steel backing plate. The deposit has been realized by means of submerged arc welding. WD1200/WD1500 wear plate is suitable for application involving severe abrasion and low to medium impact.

● WD1200/WD1500 series:

High chromium high carbon wear plates produced by submerged arc welding; Suited for applications involving severe abrasion and low to medium impact.

|

Chemicals |

Hardness |

Sheet Size |

Base Metal |

|

C – Cr – Fe |

HRC 58-63 |

1400*3500/2100*3500 |

Q235/Q345. etc |

| Chemical Composition(%) |

C |

Cr |

Mn |

Si |

Fe |

Other |

|

3.0-6.0 |

25.0-45.0 |

1.0-3.0 |

1.0-3.0 |

Bal. |

- |

|

| Hardness |

HRC 58-65 |

|||||

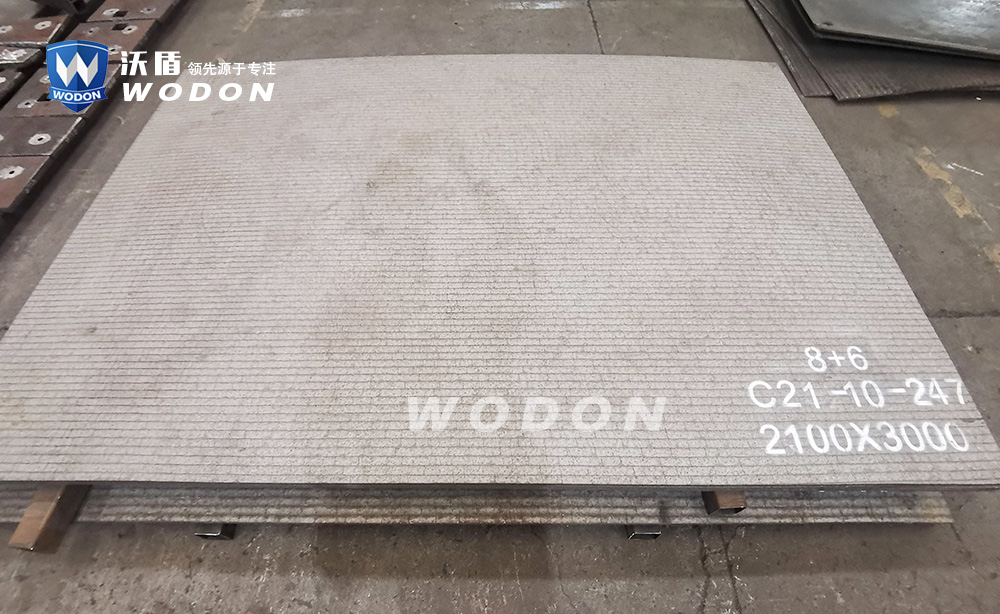

| Standard Thickness(mm) |

4+4; 5+5; 6+4; 6+6; 8+6; 8+8; 10+6; 10+8; 10+10; 12+12; 12+17; etc (overlay thickness up to 50mm) |

|||||

| Standard Sheet Size(mm) |

1400*3500; 2100*3500; (Customized size available) |

|||||

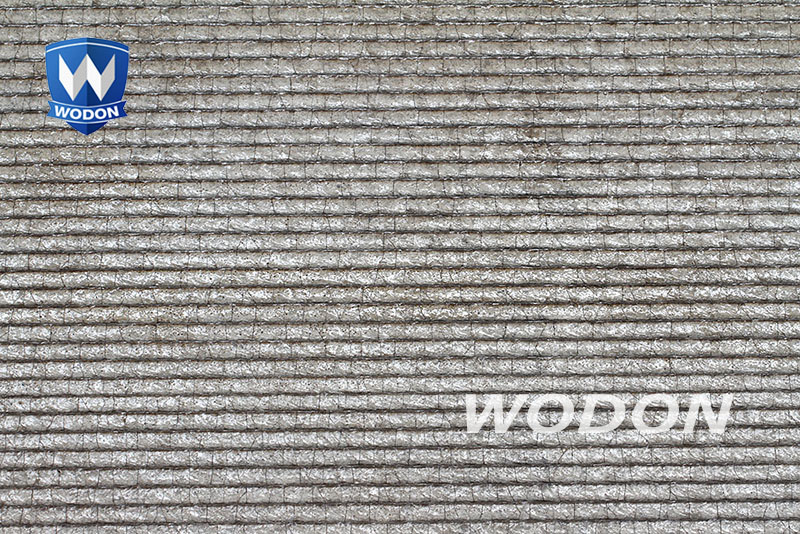

| Micro structure |

Carbide volume fraction up to 50% |

|||||

| ASTM G65 Procedure A |

0.09 - 0.16g |

|||||

| Operating Temperature |

<400 ℃ |

|||||

| Base Metal Material |

Q235B, Q345B; A36; S235JR and structural steels |

|||||

| Main Industry |

Mining, glass industry, cement plant, steel mill, power plant, etc |

|||||

| Fabrication |

Plasma cutting, Gouging, Countersunk, stud bolt, Bending |

|||||

Characteristics:

* Chromium carbide overlay wear resistant plate

* By submerged arc welding technology

* Chemical Composition: C: 3.0-6.0% Cr: 25-45%

* Chromium carbide Cr7C3 volume fraction about 50%

* The thickness of wear resistant layer can reach up to 50 mm

* Heat resistance up to 600°C

* Lager standard wear resistant area 1400*3000mm, 1400*3500mm, 2100*3500mm

* Better flatness with smooth surface

* Hardness: HRC58-65

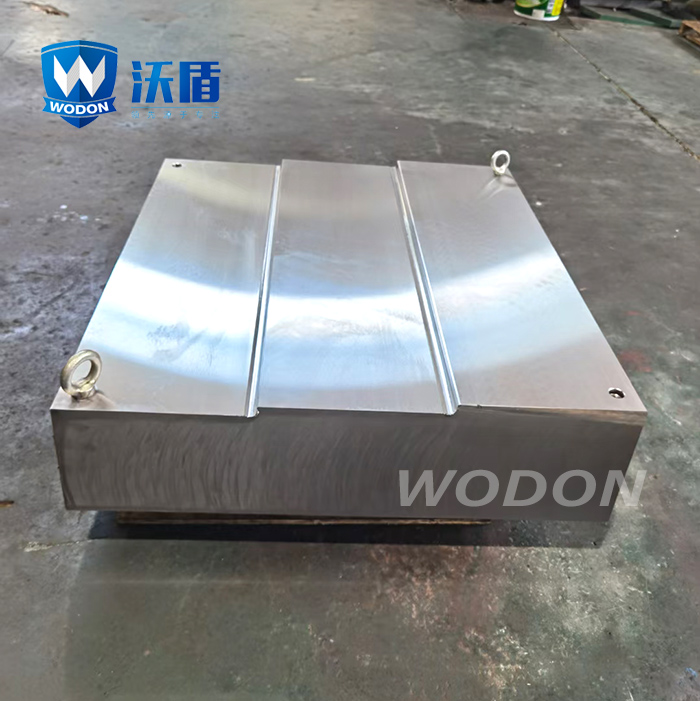

WD1200 Wear plate after bending

Note:Carbon and Chromium content varies in different plate.

Product detail pictures:

Related Product Guide:

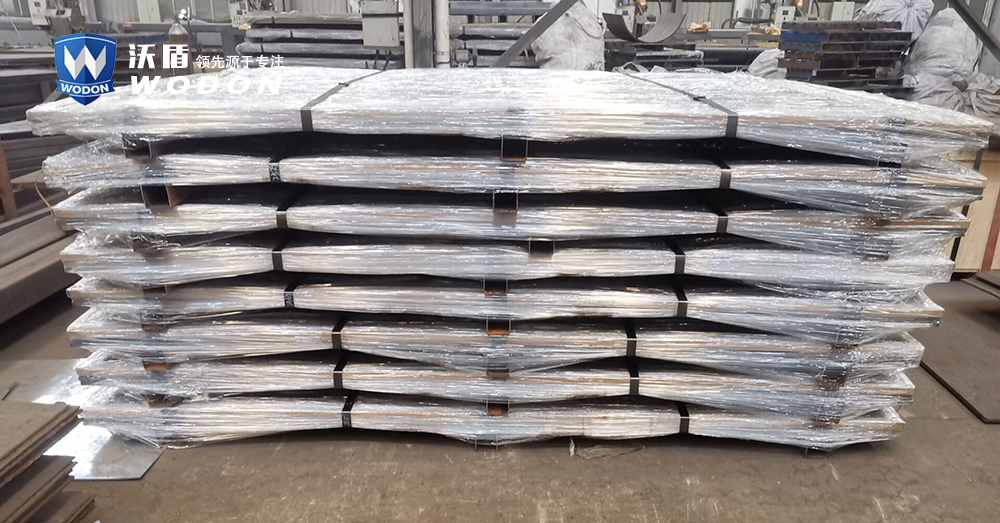

To create extra value for customers is our enterprise philosophy; buyer growing is our working chase for Free sample for Wear Plate Steel - WD1200/1500 Wear Plate – Wodon , The product will supply to all over the world, such as: Jersey, luzern, Swiss, We'll continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.