Factory Cheap Hot Wear Resistant Plate - WD1000/1100 Wear Plate – Wodon

Factory Cheap Hot Wear Resistant Plate - WD1000/1100 Wear Plate – Wodon Detail:

WD1000/WD1100 series

Abrasion Resistant Chromium Carbide Overlay

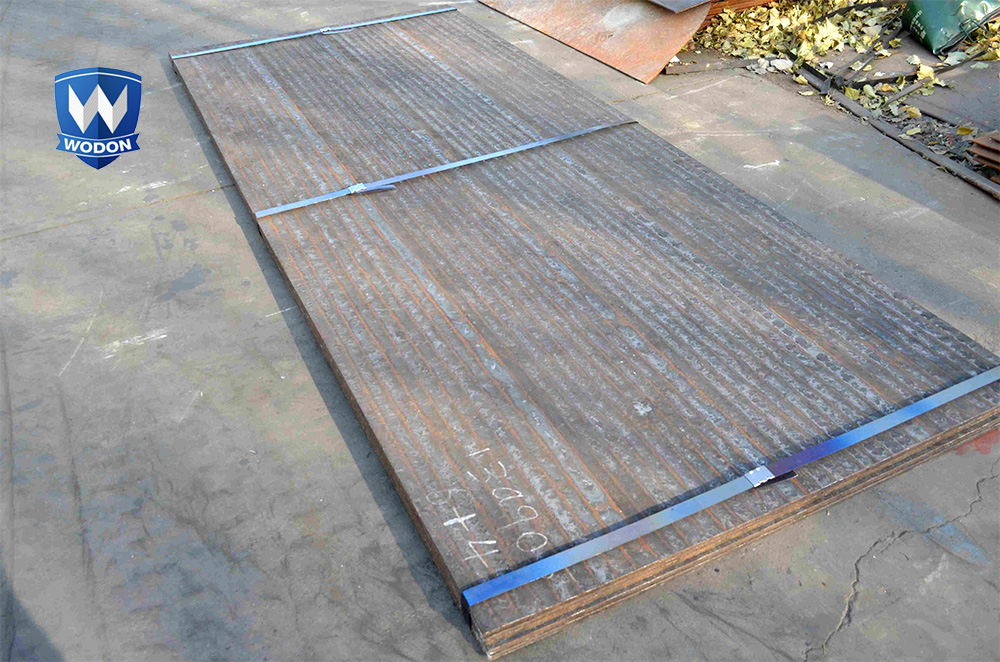

WD1000/WD1100 is chromium carbide composite cladding fusion bonded to a mild steel backing plate. The deposit has been realized by means of flux cored arc welding. WD1000/WD1100 wear plate is suitable for application involving high abrasion and low to medium impact.

● WD1000/WD1100 series:

Common chromium carbide wear plates produced by flux cored arc welding; Suited for applications involving high abrasion and low to medium impact.

|

Chemicals |

Hardness |

Sheet Size |

Base Metal |

|

C – Cr – Fe |

HRC 58-63 |

1400*3400 |

Q235/Q345. etc |

| Chemical Composition(%) |

C |

Cr |

Mn |

Si |

Fe |

Other |

|

3.0-5.0 |

15.0-35.0 |

1.0-3.0 |

1.0-3.0 |

Bal. |

- |

|

| Hardness |

HRC 58-65 |

|||||

| Standard Thickness(mm) |

3+3; 4+4; 5+5; 6+4; 6+6; 8+4; 8+6; 8+8; 10+10; 12+12; etc (overlay thickness up to 50mm) |

|||||

| Standard Sheet Size(mm) |

1400*3400; 1500*3000; 2000*3000; (Customized size available) |

|||||

| ASTM G65 Procedure A |

0.12 – 0.18g |

|||||

| Operating Temperature |

<400 ℃ |

|||||

| Base Metal Material |

Q235B, Q345B; A36; S235JR and structural steels |

|||||

| Main Industry |

Mining, glass industry, cement plant, steel mill, power plant, etc |

|||||

| Fabrication |

Plasma cutting, Gouging, Countersunk, stud bolt, Bending |

|||||

Remark:

We can customize the plates in different sizes and thickness based on customer’s drawings. we can also cut, bend and weld the wear plates into specific shapes and parts

Characteristics:

* By open arc welding technology

* Chemical Composition: C: 3.0-4.5% Cr: 15-35%

* Chromium carbide Cr7C3 volume fraction about 40%

* The thickness of wear resistant layer can reach up to 50 mm

* Heat resistance up to 600°C

* Lager standard wear resistant area 1400*3400 mm; 1500*3000 mm; 2000*3000 mm

* Better flatness with smooth surface

Note:Carbon and Chromium content varies in different plate.

Product detail pictures:

Related Product Guide:

We believe that prolonged time period partnership is really a result of top of the range, benefit added provider, prosperous knowledge and personal contact for Factory Cheap Hot Wear Resistant Plate - WD1000/1100 Wear Plate – Wodon , The product will supply to all over the world, such as: Holland, South Africa, Berlin, We are very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We provide one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!